New Facts For Laser Processing Prague Mint Coins

New Facts For Laser Processing Prague Mint Coins

Blog Article

How Can High-Precision Cnc Machines Cut Out Designs Into A Master Hub, Or Die For Striking Gold Medals Or Coins?

High-precision CNC (Computer Numerical Control) machines play an essential part in the design of dies or master hubs for the creation of gold coins and medals. The following is an overview on the preparation of CNC programming.

The CAD software (Computer Aided Design) is used to create an electronic 3D model of a medal or coin design.

CAM (Computer Aided Manufacturing), software that creates toolpaths, commands and instructions for CNC machines built on 3D models.

Choice of Die Material

CNC machining of dies and master hubs is performed on tough materials such as steels, brasses, and hardened alloys. These materials can withstand high pressure striking processes and ensure exact reproduction of the designs.

Fixture and Setup

For precise machine work, the material is secured to the CNC machine's table or vice. It is essential to fix the workpiece properly in order to reduce vibrations while the machining.

CNC Machining Process

CNC machines use end mills as well as ball mills as cutting tools to carve designs into dies or master hubs.

The CNC machine will follow programmed toolpaths to remove material from the blank block according to the 3D design specifications.

Cutting tools of different sizes and types can be used to create different depths, contours and details on the coin or medal.

CNC machines are controlled by computer algorithms to guarantee precision to micrometer-level tolerances.

Finishing, Refinement and finishing

After the initial machining has been completed, the die hub or master die gets then refined further.

Polishing, smoothing, and sanding by hand or using specialized tools ensure the surface finish meets the requirements for.

Quality Control and InspecQuality Control and Inspec

The final die or hub is then put through to a thorough inspection using the aid of measurement instruments like gauges, micrometers and optical measuring instruments to ensure it is in compliance with all design specifications.

Treatment and Hardening (optional).

Some dies may undergo heat or surface treatments to improve their durability.

The precision and power of CNC machines allows for exact reproduction of intricate designs onto master hubs or dies. Die machines are the essential tooling needed to make gold medals or coins with consistency, accuracy, and fine details. Have a look at the top CNC Machining Prague Mint gold medals site info including gold panda coin, 1oz gold, maple leaf gold coin, gold and silver dealers, 1oz gold, guardian angel coin, american eagle gold coin price, gold bullion bars, sd bullion gold, gold coin with angel on both sides and more.

How Does Laser Technology Work To Polish The Gold Surface Or Medal Die?

Laser technology is utilized in the production of dies or master hubs for gold medals or coins to obtain exact detail and refine the surface for better accuracy. This is the way laser technology is utilized in this process Surface Refinement

The master hub's surface is re-polished with laser technology after initial machining. It aids in smoothing out flaws, removing burrs or minor irregularities in the surface.

Detail Enhancement-

Laser ablation or engraving techniques are used to enhance or add details on the master hub or die. Lasers can precisely etch and remove material to create precise lines and textures or complex designs that are difficult to achieve using traditional machining.

Microstructuring-

Laser microstructuring involves creating microstructures or patterns on the surface of a die. This technique can be used to add specific patterns or textures to improve the aesthetic appeal or security characteristics of medals or coins.

Surface Hardening and Treatment

Lasers can be used to treat or strengthen the surface of dies or master hub. This process improves the wear resistance and durability that ensures the longevity of the striking process.

Precision Modifications

Laser technology permits precise corrections and adjustments to the die or the master hub, without affecting the overall geometry. It enables modifications to be made to the surface of the die, and addresses any discrepancies or imperfections which could impact the overall quality of medals or coins.

Controlled Material Removal

Laser ablation allows for precise material removal. This is especially useful in areas that require fine specifics to be defined. It is a non-contact method of material removal, preserving the integrity of surrounding area.

Laser technology can be utilized to refine the surface of master hubs and dies and master hubs, which result in more clarity, better surface quality, and increased precision. It complements conventional machining processes that allow for the precision manipulation and enhancement of the characteristics of the die's surface critical for striking high-quality gold coins or medals. View the top laser processing Czechoslovakia gold coins website tips. including gold buy bullion, gold silver shops near me, angel coin, 50 dollar gold piece, sell gold silver near me, 1oz gold, buy gold bars from bank, gold bullion price today, gold and coin dealers near me, 1999 gold quarter and more.

What Is The Reason And How Are Gold Blanks Of Superior Quality Weighed And Measured Prior To The Minting Process Starts?

This procedure is used to create gold-plated coins and medals of top quality. The preparation process for gold blanks will be explained below. The gold is usually refined to meet the specific quality standards for coinage.

Gold Blanks Production - Gold can be made into blanks using a method called blanking, or blank-cutting. Blanking involves cutting coin-sized disks or planchets of gold by using specially-designed machinery or stamping processes.

Precision Weighing and Measuring

Weighing Each piece is weighed individually to ensure that it satisfies the criteria to be used for the coin. This process guarantees that every piece has the exact amount of gold that is required for the denomination.

Measuring. Instruments that are precise are used for measuring the height, diameter, and the dimensions of every blank. This assures uniformity and conformance to design specifications.

Inspection and quality control

Visual Inspection- Each Blank is inspected visually to find imperfections in the surface.

Rejecting Blanks that Are Not Compliant- Blanks are rejected if they are not in compliance with the weight, size, or any other quality standards. This is done in order to keep uniformity and consistency.

Why is it important to prepare?

Consistency in Minting Process. Precisely weighted and measured blanks ensure uniformity during the minting procedure. Consistency is essential to ensure uniformity during the process of striking, which means that medals and coins with the same high-quality.

Affordable Weight of Gold Each gold bar is weighed precisely, which ensures accuracy in quality and purity.

Uniform Blanks - Avoid variations of weight or size which may impact on the value of the coin or medal and legality, or its suitability for circulation or commerce.

Quality Assurance - Strict measures of quality control throughout the blank preparation process ensure that only the highest quality and defect-free blanks are sent to the stage of minting which reduces the chance of flaws forming in the final product.

Legal Compliance - It is important that coins for use in circulation or for commemorative purposes conform to the specifications and comply with legal specifications.

The precision and consistency in preparing high-quality gold blanks are crucial steps in the process of minting, which ensures the production of precise, high-value, and legally compliant gold coins or medals. Follow the top rated gold blanks for Czechoslovakia gold coins website advice including gold price coin today, angel coin, ebay gold coins, gold bullion for sale, sell gold silver near me, gold apmex price, 1 10 gold eagle, gold coins and bullion, 1 10 american gold eagle, 1 10 gold eagle and more.

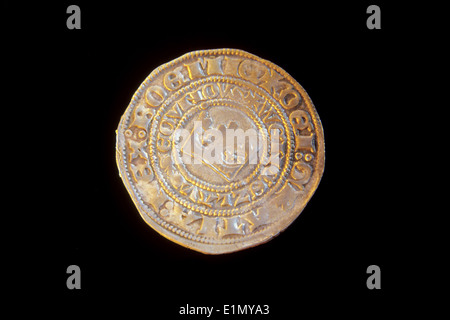

How Do Gold Medals And Coins Get Their Antique Or Aged Look?

Here's how and the reason this is performed. How and why is this done?

Chemical patination. The coin or medal is treated with acid or solution that creates patina. These solutions trigger a controlled oxidation and tone to give the appearance of antique coins. This process can highlight details and give depth to the design.

Artificial Aging- Mechanical or chemical methods are used to simulate the aging process, simulating the natural wear and tarnish that happens with time. Abrasive treatment or tools can cause scratches or worn areas to create a more aged appearance.

Toning and Staining: Specialized solutions, or heating treatments are utilized to tone or stain the surfaces. The result is a variety of shades or hues. This method can mimic the discoloration, toning and fading that naturally occurs in the course of time.

Buffing, Polishing Techniques: Specific areas can be selected for a specific buffing process to eliminate surface highlights or layers. This creates an appearance of contrast and gives the appearance that wear has taken place.

What are the motivations behind creating an antique appearance?

The look of antique is appealing to some collectors and enthusiasts. The aged appearance gives depth and character to the style. It's visually stunning.

Historic or Commemorative Significance Coins or medals commemorating historical events or periods might undergo aging to create a sense of historical authenticity or to mimic coins from a certain time.

Coins and medals that are antique are more desirable. Collectors who are looking for unique or limited edition pieces typically prefer antique coins or tokens. The appearance of their aging can increase the value of their collectibles.

Highlighting the Details - Aging will bring out the specifics in the design. Through creating contrasts between raised and receded zones, the design elements are more noticeable and apparent.

Artistic Expression: Minting authorities or artists can employ the ageing techniques as a method of artistic expression to create depth, narrative or symbolic.

Give a vintage look to gold coins or other medals as a deliberate art selection. It could evoke memories of fond memories, create visual intrigue, or convey the past. It is essential to find a balance between the aesthetics as well as the intrinsic value of the coin. Read the recommended antique finish of Prague Mint gold coins blog info. including gold coin gold, bullion dealers, 1 ounce of silver, gold bullion price, price of 1 oz of gold, coin buy silver, silver double eagle, gold quarter 2000, 1936 olympics jesse owens, gold coin with angel on both sides and more.